A Comprehensive Guide to Different Types of Galvo Scanners and Their Applications

Galvo scanners, recognized for their rate and accuracy, are essential to a variety of sectors from producing to medical modern technology. The journey to choosing the ideal galvo scanner for your functional demands begins with comprehending these subtleties.

Basic Review of Galvo Scanners

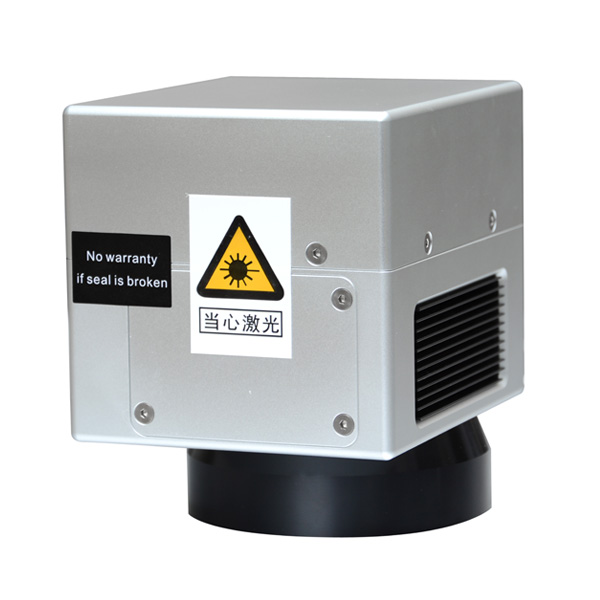

Galvo scanners, short for galvanometer scanners, are accuracy tools utilized to guide laser beams properly and rapidly across a marked area. These gadgets play a pivotal role in various markets, including medical, production, and study, by assisting in high-speed and high-precision laser applications. Essentially, a galvo scanner includes a little, light-weight mirror affixed to a galvanometer, which is an electromechanical device that measures electric present by deflection of a needle. In this context, the galvanometer's deflection mechanism relocates the mirror to steer the laser beam.

The core principle behind galvo scanners is the quick and precise control of the mirror's angle, which subsequently changes the instructions of the laser light beam. This is achieved via a closed-loop responses system that guarantees the mirror's placement is continually monitored and readjusted for precision. The feedback system comprises placement sensors, control electronic devices, and high-performance electric motors, supplying remarkable responsiveness and precision.

Galvo scanners master applications needing recurring and detailed laser activities, such as laser inscription, reducing, and clinical imaging. Their capability to operate at high rates without giving up precision makes them crucial in situations demanding both effectiveness and precision.

Sorts Of Galvo Scanners

When discovering the kinds of galvo scanners, it's vital to understand that variants are largely based on their layout, application requirements, and performance specifications. Normally, galvo scanners can be categorized into single-axis and dual-axis designs.

Dual-axis galvo scanners, on the other hand, offer two-dimensional control of the light course. This makes them vital in more complicated applications like laser light shows, 3D printing, and medical imaging. Dual-axis versions are normally equipped with 2 mirrors and equivalent galvanometers, allowing for dynamic control over both X and Y coordinates.

Trick Functions to Take Into Consideration

When choosing a galvo scanner for your certain application,Numerous essential features need to be carefully examined. Speed is a crucial characteristic, as it establishes the scanner's capability to deal with high-frequency jobs efficiently. The speed is typically measured in terms of response time and the optimum number of factors per second the scanner can deal with.

One more crucial attribute is the scanner's series of activity, which shows the maximum angular discrepancy it can accomplish. A broader array offers greater versatility yet may require extra sophisticated control systems. Thermal security additionally needs attention, as temperature level fluctuations can impact efficiency; thus, choose scanners with durable thermal monitoring systems.

Industry-Specific Applications

In different sectors, galvo scanners play a critical role by enhancing accuracy and performance in specialized applications. In the medical area, galvo scanners are indispensable to laser surgical procedures and sensory procedures, where high-speed, precise beam positioning is crucial. These gadgets allow minimally invasive surgeries by exactly targeting cells, hence reducing recovery times and enhancing patient outcomes.

In manufacturing, galvo scanners are crucial for laser engraving, cutting, and welding. Their capacity to quickly and precisely direct laser beams makes certain top notch coatings and intricate outlining, which is essential for the production of facility elements in automobile, aerospace, and electronic devices industries. The textile market also gains from galvo anonymous scanners in material cutting and inscription, providing both speed and accuracy in handling varied products.

Choosing the Right Galvo Scanner

Choosing the ideal galvo scanner is an important choice that hinges on several vital variables, including application demands, efficiency specifications, and spending plan restraints. First, clearly define the application needs. Whether the scanner is meant for laser inscription, clinical imaging, or 3D printing, each application requires certain efficiency attributes such as precision, rate, and resolution.

2nd, consider the performance specs. Specifications like scan angle, feedback time, and thermal security are crucial (galvo scanner). A high-speed galvo scanner with a broad check angle is optimal for large-area noting, while applications calling for fine detail may prioritize high resolution and accuracy

Third, account for budget restrictions. High-performance galvo scanners come with a substantial investment, however their lasting benefits can exceed preliminary costs. Review the total expense of ownership, including upkeep, to ensure the picked scanner offers worth over its life expectancy.

Verdict

Understanding the diverse sorts of galvo scanners and their one-of-a-kind capabilities is crucial for optimizing performance throughout various markets. Dual-axis and single-axis models satisfy different functional complexities, while high-speed and high-precision variations address certain needs in manufacturing, textiles, medical areas, and 3D printing. Mindful selection based on the distinct features and application requirements of each sort of galvo scanner guarantees improved effectiveness and accuracy, thereby substantially enhancing general functional results.

Galvo get redirected here scanners, brief for galvanometer scanners, are accuracy tools utilized to route laser beam of lights accurately and quickly throughout a designated area.When exploring the kinds of galvo scanners, it's critical to comprehend that variations are primarily based on their layout, application needs, and performance requirements. Each kind of galvo scanner is hence distinctively customized to fulfill particular operational needs, making certain ideal efficiency throughout various applications.

The precision of a galvo scanner directly affects the high quality of the outcome, making it vital to take into consideration the scanner's capacity to maintain high-resolution efficiency more tips here (galvo scanner). Mindful selection based on the special attributes and application requirements of each type of galvo scanner makes sure enhanced efficiency and precision, therefore significantly boosting general operational end results